Wave expression yanagi-kirituke blade|郷右馬允義弘 青波打 柳切付270mm 一位八角柄 朴鞘付属

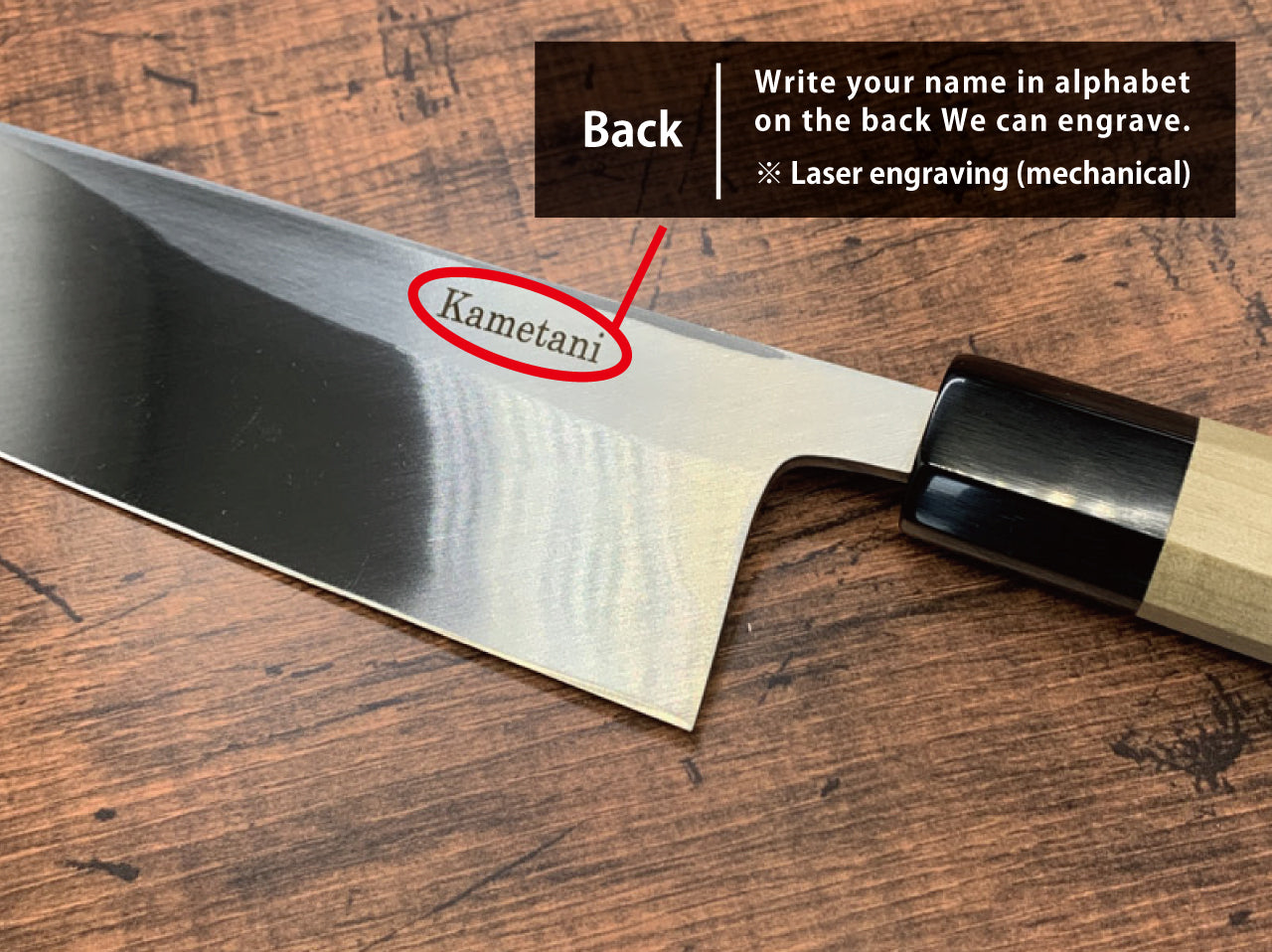

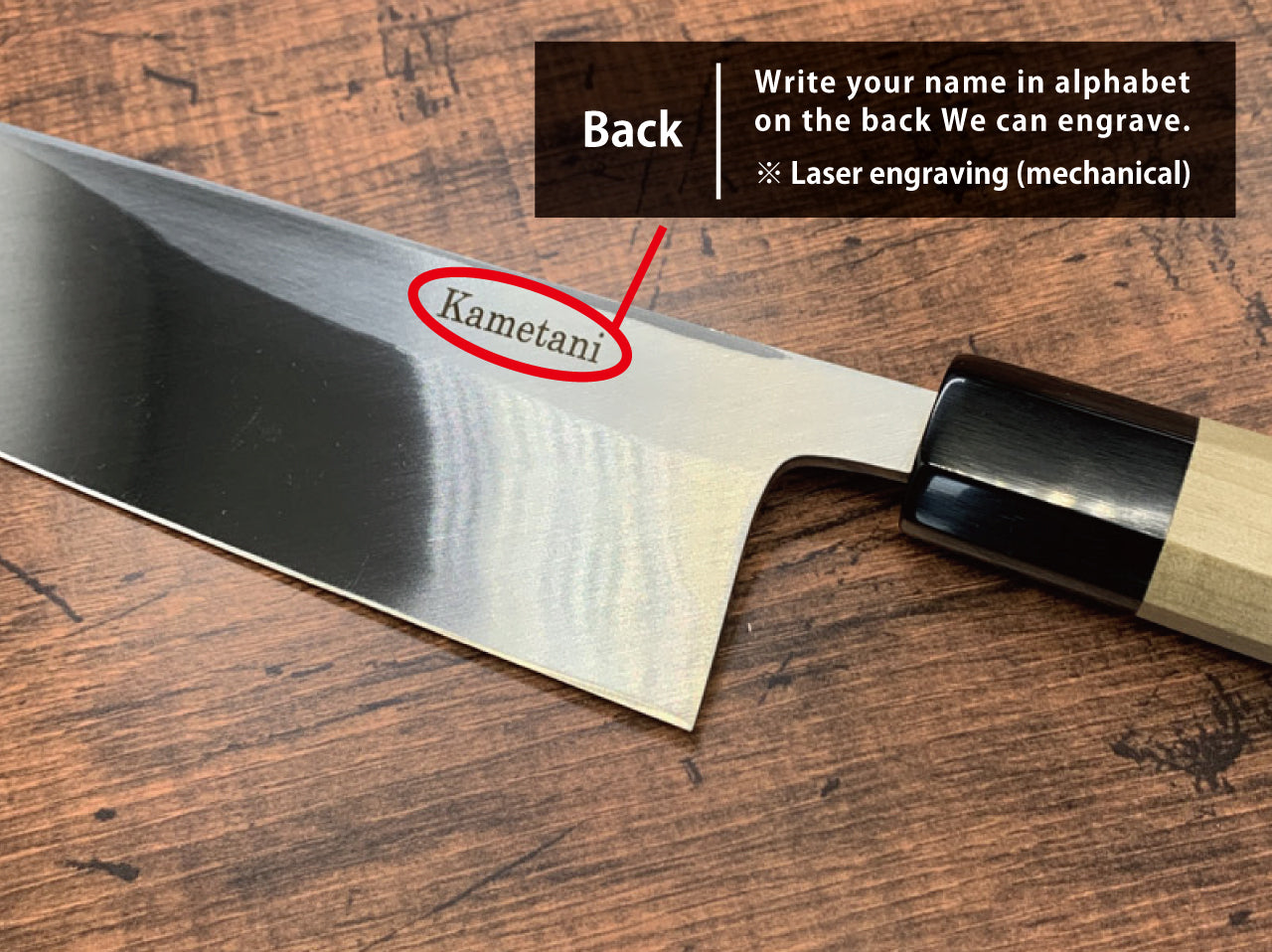

*For details on name engraving, please see here.

This knife is made of Yasugi steel Aogami No.1, the hardest of the Japanese steel family, and has both sharpness and durability.

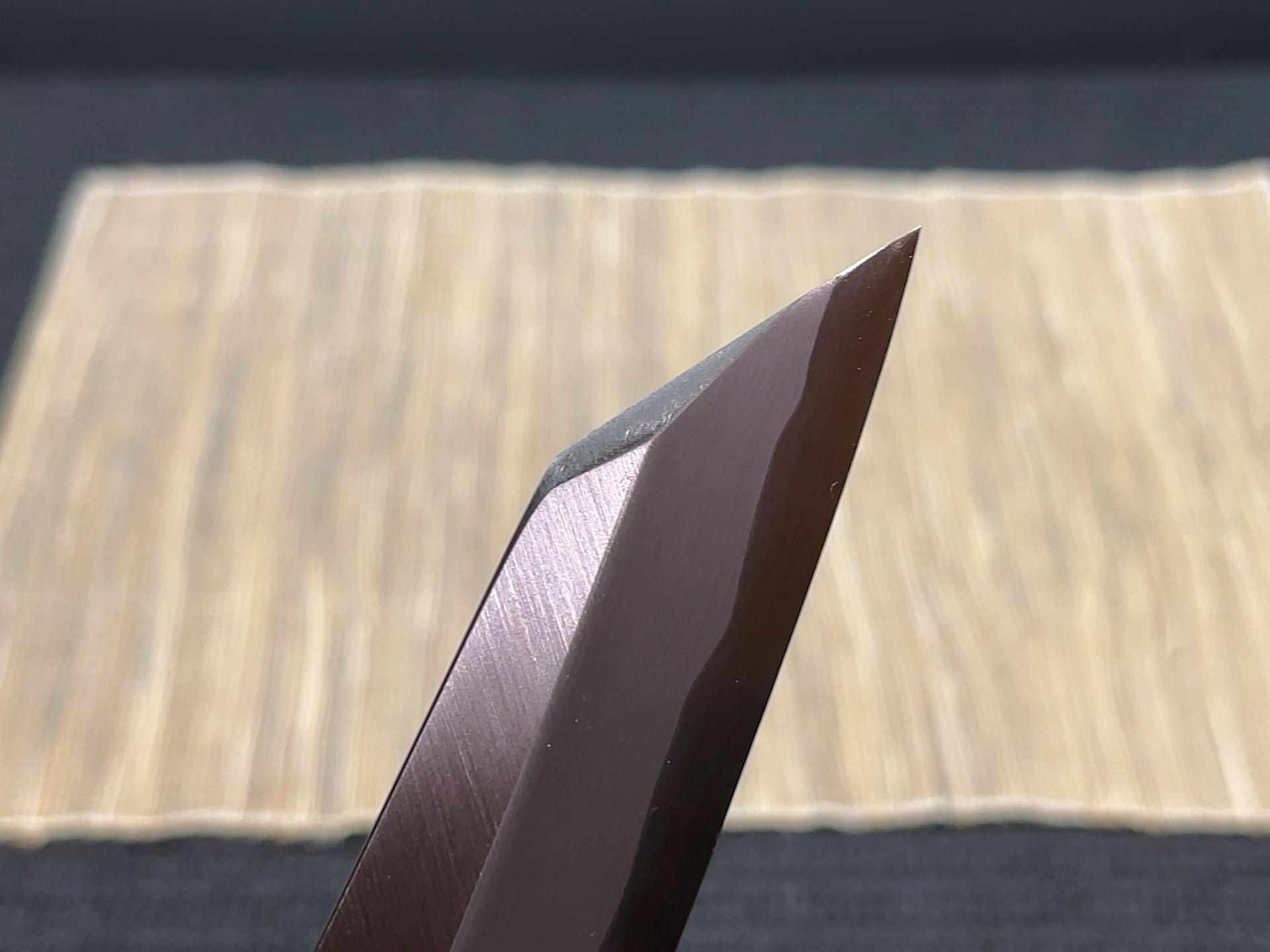

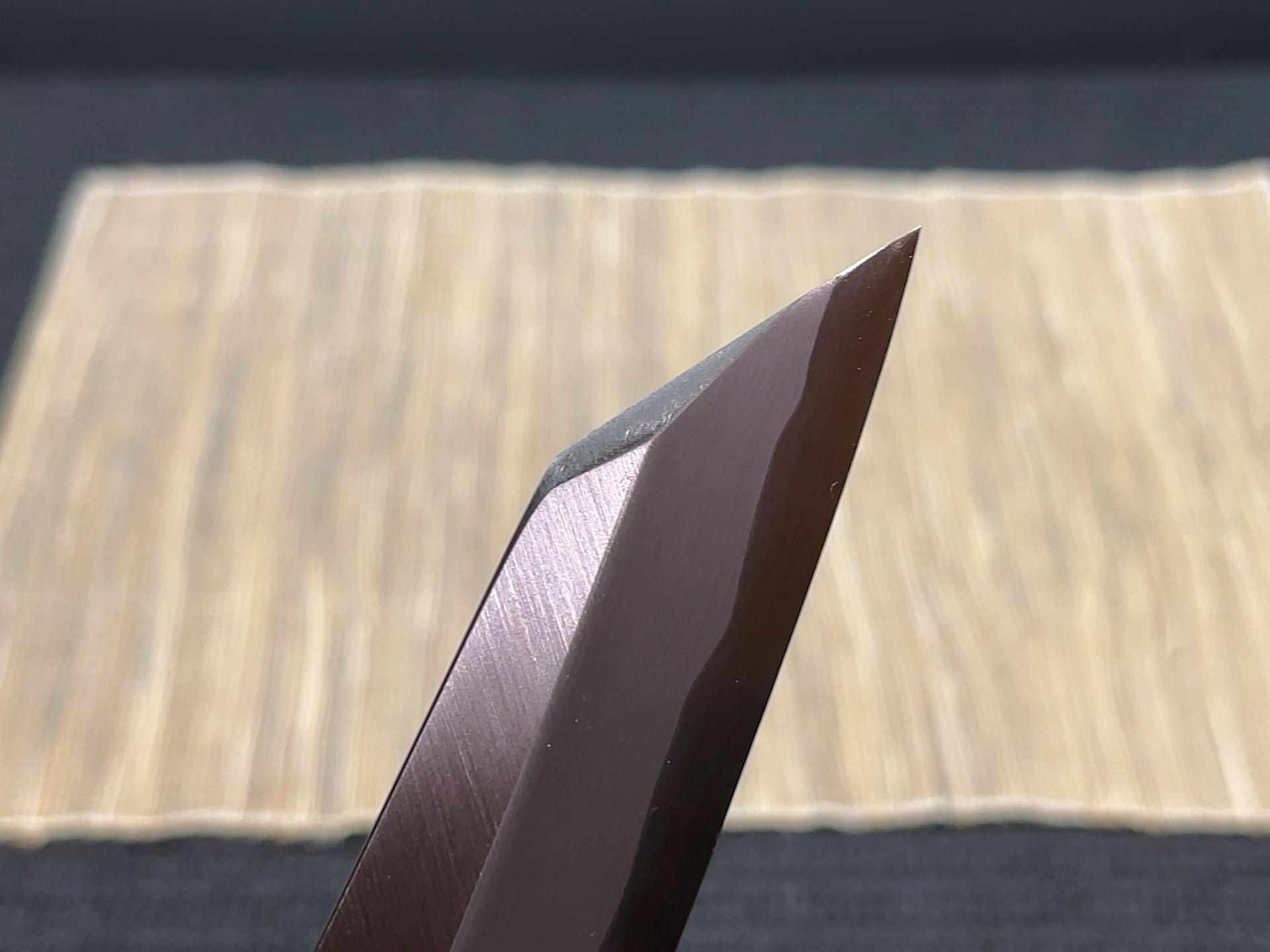

The sharp edge of the willow blade has been cut down to a sharp angle, making it more versatile than a willow blade, and the tip is easier to sharpen. This shape is quite popular overseas.

The handle is made of ippiki, a wood famous for its Itto-bori carving. It is both water-resistant and easy to hold.

| Item Number | B1HC-270YK |

|---|---|

| Shape | Kirituke-yanagi(柳切付) |

| Steel grade/blade length | Yasuki Steel Blue No.1・270mm(安来鋼青1号・270mm) |

| Knife handle |

One octagonal handle(一位八角柄) eight-patterned red kimono (worn by the nobility, etc.)(赤八柄) |

| Tsunoguchi(bolster) | Buffalo horn(水牛角) |

| Scabbard | Wooden scabbard with ebony pin(朴鞘(黒檀ピン付)) |

| Easy to rust | rust |

◆Recommended Use

Choose options

*For details on name engraving, please see here.

Knife structure

Explanation of kitchen knife terminology

The process of forging solely with steel (carbon steel) is called "Hon-yaki." Furthermore, the blacksmithing process of tempering with water is known as "Mizu-yaki." Mizu-yaki requires advanced techniques and experience, making it only possible for a select group of skilled blacksmiths. These are considered the highest-grade knives.

Fine unevenness is formed by striking the surface of the metal with a special mallet or hammer. This unevenness becomes a beautiful pattern and has a unique texture. Also, by changing the hammering method, density, direction, etc., various variations of patterns can be created.

"Honkasumi" is the most commonly used Japanese knife. Kasumi refers to knives made by combining base metal and steel. Among them, only those made by blacksmiths by sticking base metal and steel without using plywood materials can be called "Honkasumi". As a basic, "white octagonal pattern" is attached.

It is a kitchen knife made by layering different steel materials. Since multiple materials are used, the merit is that many of them have high hardness and durability, and are excellent in sharpness. It is characterized by a wave-like pattern on the surface of the blade, and you can also enjoy the beauty of the appearance.

This is a technique that polishes the surface of metals and other materials to give them a mirror-like luster. Along with the beautiful appearance, it also leads to improved sharpness and durability.

Typical high-grade cutlery steel used for Japanese knives. It is difficult to handle and depends on the skill of the craftsman, but if handled by a skilled blacksmith, it can be sharply sharpened, has moderate stickiness, can be cut for a long time, and can be finished as a high-quality knife that is easy to sharpen.

By hitting the metal material with a special mallet or hammer, fine unevenness is added to the surface. This unevenness creates a beautiful pattern and is characterized by its unique texture.

The pattern on the knife resembles the pattern created when ink is dropped and mixed in water, hence it is called a "Suminagashi" knife. The Suminagashi knives that we handle on our site are made of a main steel (such as Yasuki Blue #1 steel) combined with laminated soft iron.

It is one of the methods of quenching knives, in which water is used to cool the heated knives. It rapidly lowers the temperature of the metal compared to "oil grilling" that uses oil. Sudden temperature changes often cause distortion and cracking, which tests the skill of the craftsman.

"A type of very high quality steel that is said to have been produced in the ancient Syrian city of Damascus. Generally, it is often used for forged swords and cutlery, and is characterized by beautiful patterns.

The manufacturing method of Damascus steel requires extremely advanced technology, and multiple different types of iron and steel are layered and forged to create a dense and strong steel."

High-grade stainless cutlery steel with added chromium, molybdenum, vanadium, etc. to improve hardness and wear resistance. Because it is a material with a large amount of carbon, it can be hardened by proper quenching, and has a sharp edge and is more resistant to rust than general stainless steel.